Experience

PanelClaw’s deep experience in flat roof provides a competitive advantage to partners working with us on their projects. Everything we do is geared toward accelerating the worldwide adoption of PV.

JAN 2024

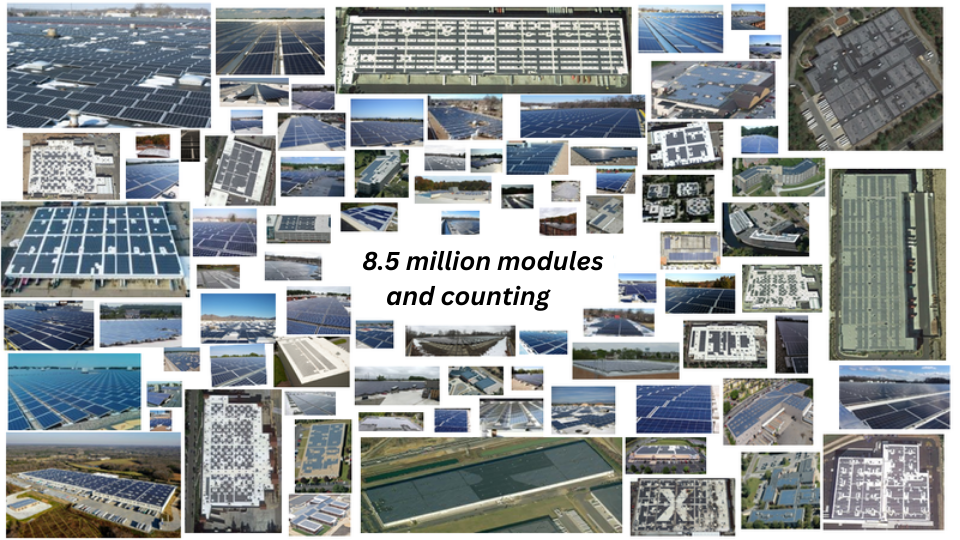

PanelClaw’s flat roof project experience

No one has more flat roof experience than PanelClaw. This experience translates to a competitive advantage for our partners.

- Flat Roof installations in more than 35 countries around the world

- over 13,000 projects completed

- unmatched 99.997% reliability track record

- Projects ranging from 5kW to 20MW on a single roof

- successfully permitted flat roof projects with more than 2,000 U.S. permitting offices, Including the most demanding ones.

- installations in 47 states plus Puerto Rico in the US, includes the most stringent wind, seismic and snow conditions.

Testing & Certification Data Program

PanelClaw’s test data program is the most advanced in the industry, It encompasses a mixture of in-house and third-party expert testing coupled with rigorous in-house and outside peer review protocols. The result is the unmatched reliability track record of our flat roof mounting structures for our partners and their customers.

Our test program includes, but is not limited to:

1. ANSI/UL2703-2015

- Electrical – bonding & ground path resistance testingBonding path resistance;

Thermal cycling (TC-200);

High current bonding conductor 125% and 200%; and

Freeze/thaw (HF-10). - Mechanical – load testing

- Positive load;

Negative load; and

Down-slope load. - Fire – spread of flame testing

2. Mechanical Load Transfer testing (lateral E/W/N/S) to show compliance with SEAOC guidelines given PanelClaw’s Automated Wind and Seismic Design (AWSD) software algorithms and array layout rules.

3. Vertical lift testing to determine Effective Wind Areas for use in wind design methodology

4. Coefficient of friction testing following ASTM G115

5. Boundary layer wind tunnel testing – spanning more than 8 years of annual testing

6. Mechanical Load tests for mechanical attachments

7. 1,500 hour salt spray corrosion testing

8. Lateral stiffness testing on tilted table to evaluate all connection points

9. Roof wear testing to validate efficiency of roof protection pads

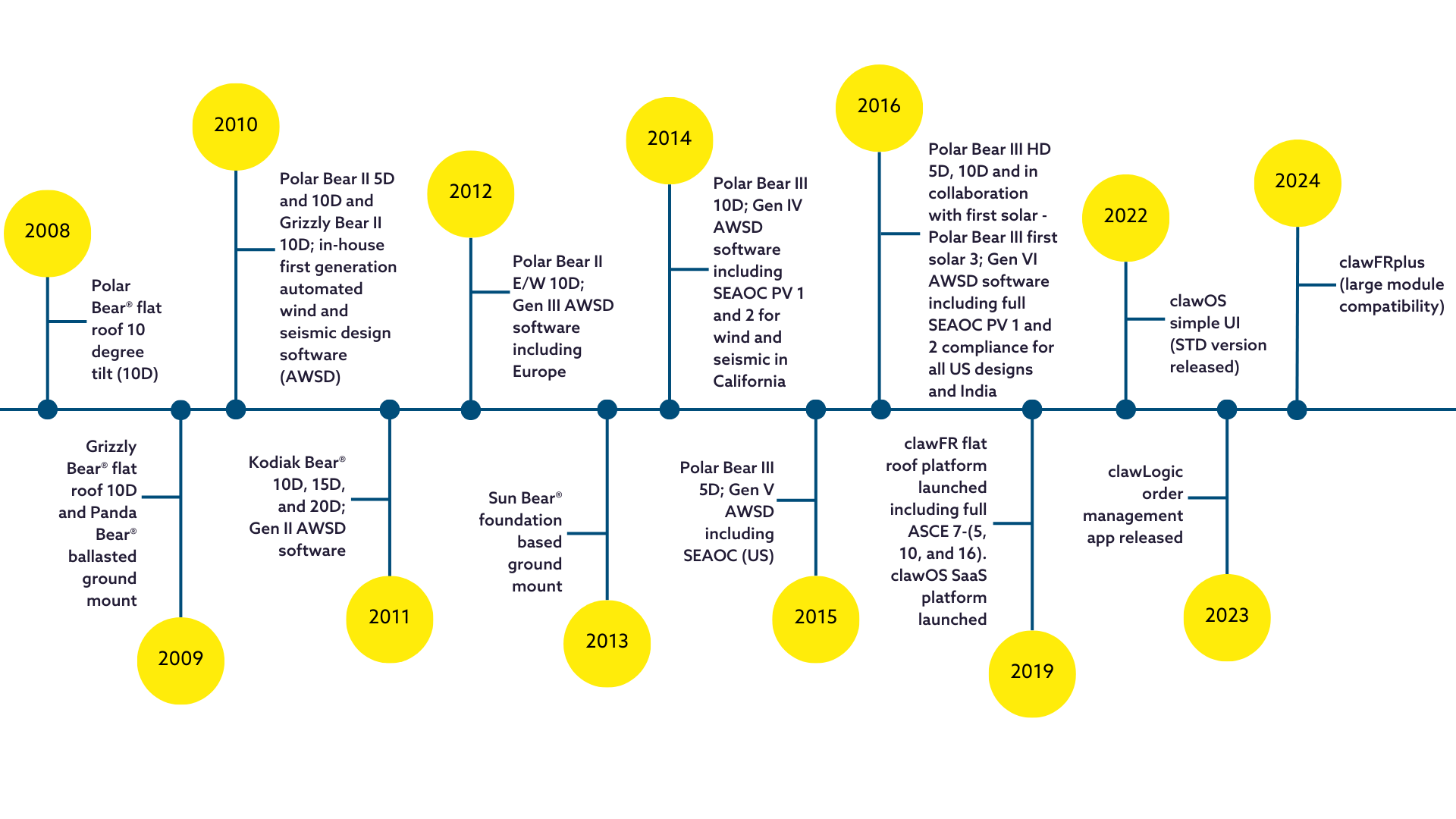

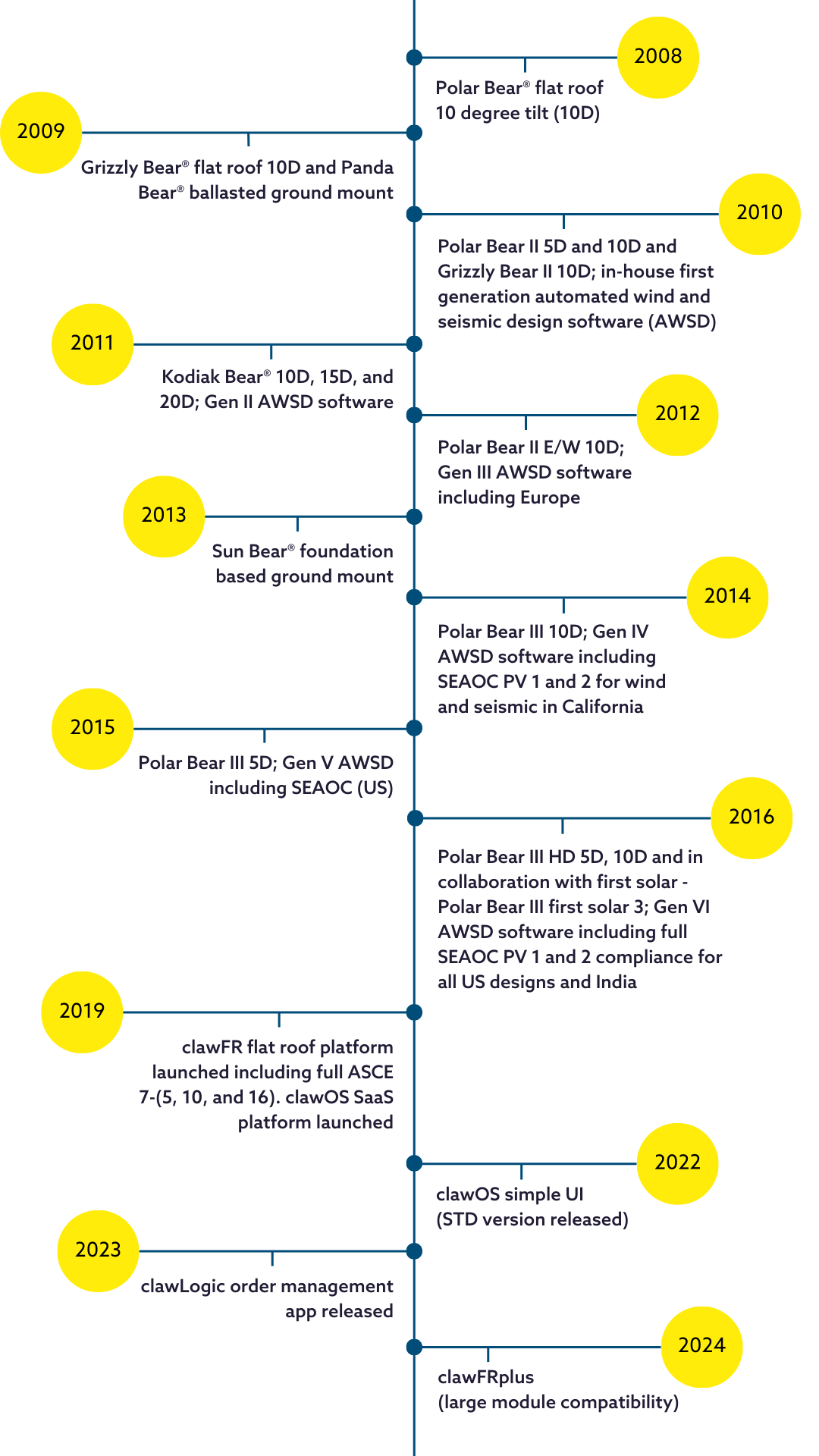

PanelClaw’s Innovation

During its 15 year history, PanelClaw has launched nine flat roof products which have progressively lowered the life-cycle-cost of rooftop PV while delivering unparalleled product reliability under even the most challenging environmental, permitting, and building site conditions. In the last 5 years, PanelClaw has invested heavily in software tools that enable its customers to accelerate the project development process from beginning to end (initial bidding through decommissioning).

PanelClaw Product Evolution